COMPANY

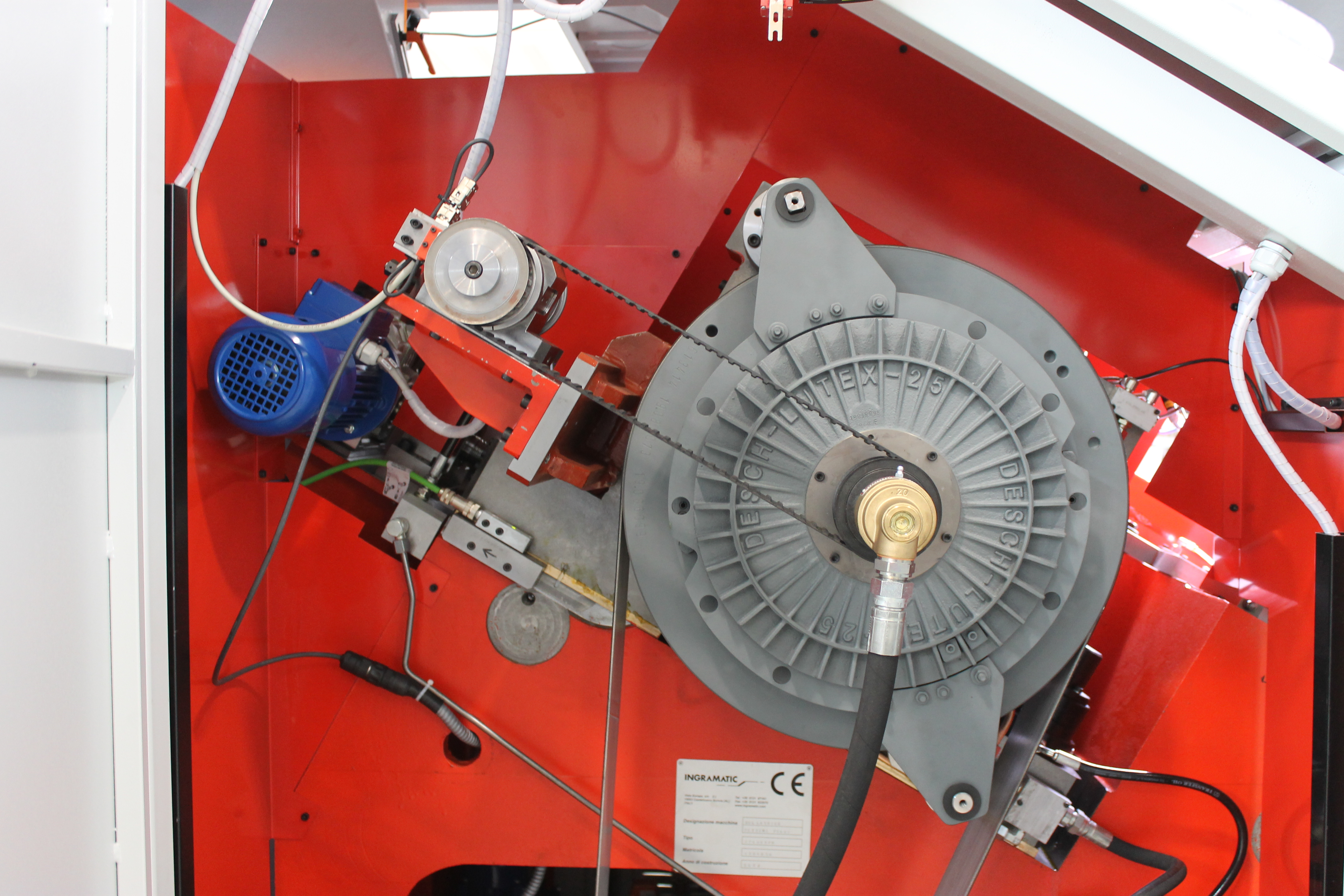

Ingramatic is a company with many years of experience in the production of machines for the rolling of screws and bolts. It was set up in 1966 and has since produced and distributed over 4000 thread rolling machines worldwide becoming a market leader around the World. In 2006 a new plant was built in Castelnuovo Scrivia covering a surface area of 20,000 square metres. This marked a turning point in terms of logistics, organisation and efficiency towards meeting new targets.

Ingramatic has been part of the Sacma group since 2004 creating a unique technical, productive and commercial alliance.

Our products complement the Sacma production range and can be used along with progressive die headers for the thread rolling of high-strength screws, bolts and special fasteners.

All the mechanical components used for assembly are manufactured at the Ingramatic and Sacma plants in Castelnuovo Scrivia, Limbiate and Vimercate.

The manufacturing, pre assembly, assembly, testing, warehouse and technical departments are all located at the Castelnuovo Scrivia plant. With a range of thread rolling machines suitable for small or large components into the automotive, building and general industries. Even a range of warm threading machines are available for the aerospace market. Our products represent unrivalled reliability, productivity, safety and innovation.

Ingramatic supplies combined machines to run special multi shape parts with only one step with the possibility to install the rotative station before the regular flat dies thread rolling station. Ingramatic has used its knowledge to develop standard machines in conjunction with washer assembly units, pointing units, rotative thread rolling unit with special customised versions available upon request. Ingramatic does not just manufacture machines, it offers complete production systems. Automatic feeders for blanks and washers, stress control monitoring combined with rejection control devices, with the washer assembly and pointing units being easily integrated with Ingramatic thread rolling machines due to their modular design.

HIGHPRECISION

Products in today’s markets require very precise and repeatable threaders that can only be manufactured with ultra precise machining of the components.

Only the highest quality of the materials, design and manufacturing can provide highly efficient and reliable threaders.

To take advantage of the most innovative manufacturing technology and advanced machine tools available, all INGRAMATIC mechanical components are machined within the SACMA Group plants. This not only provides ultra precise machining of the components but also gives INGRAMATIC total quality control over its products.

A systematic, stringent final inspection of all parts prior to delivery and inventory ensures the best guarantee of conformity and interchangeability.

The choice of high strength materials combined with the use of sophisticated heat treatments and extreme precision of surface grinding and lapping finishes make Ingramatic thread rolling machines fast and reliable with the lowest operating costs.

BASE

The base is critical to the performance of a machine tool and especially a thread rolling machine since it affects its overall precision and reliability. Years of experience and research using extremely sophisticated simulation systems and experimental deformation analysis are vital to this component.

For machines up to RP620, the bed frame is made of pearlitic spheroidal cast iron, which provides good damping of vibrations generated by the high production speed.

From RP720 to RP920, Ingramatic makes the frames from electrowelded steel plate with “C” stiffener and has undergone thermal stress relieving before machining on Sacma's high precision machine tools to ensure high stress resistance .

The base is fixed to a platform that supports it and serves as a collection tank for the coolant. From a structural point of view, it results in an extremely rigid system with optimum management of technical fluids without the risk of dispersion into the work environment.

The new design optimised using FEM software helps to counter the stresses caused by rolling heat-treated workpieces and special profiles.

MODULAR SYSTEM

The concept of modularity in the design and construction of machines has significant advantages for the users. It facilitates system customization based on customer needs and requirements, while providing the most efficient method of parts inventory and assembly. Even retrofitting of existing systems becomes much simpler.

In collaboration with SACMA, INGRAMATIC is the only threader manufacturer that builds its machines using the modular system concept, assuring all Ingramatic machine parts always available in the warehouse.

The thread rolling machines have been designed to incorporate accessories including:

- Single washer assembly units,

- Double washer assembly units,

- Pointing units,

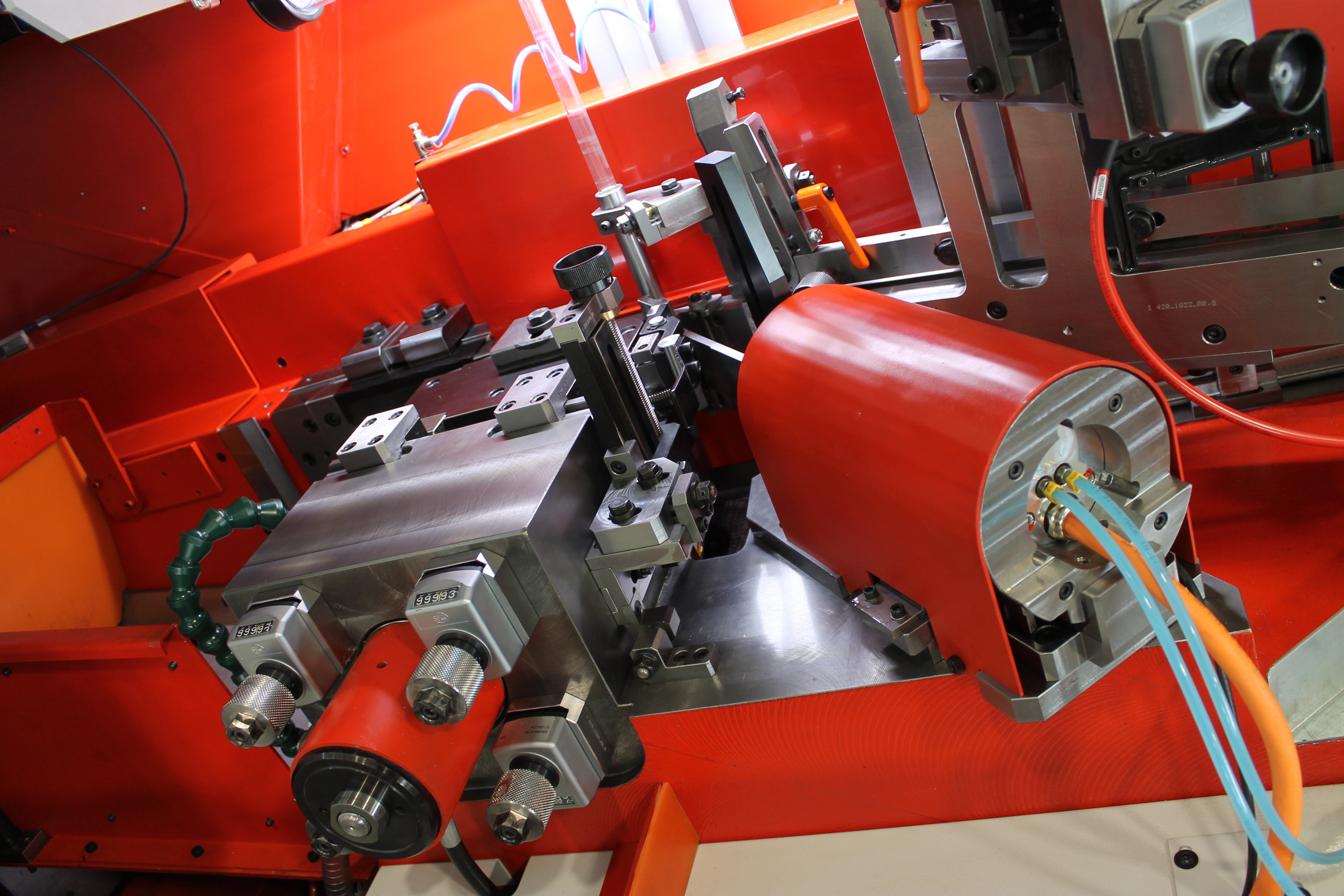

- Rotative thread rolling units for combined threading operations,

- Feeding systems for stud bolts and special headless screws,

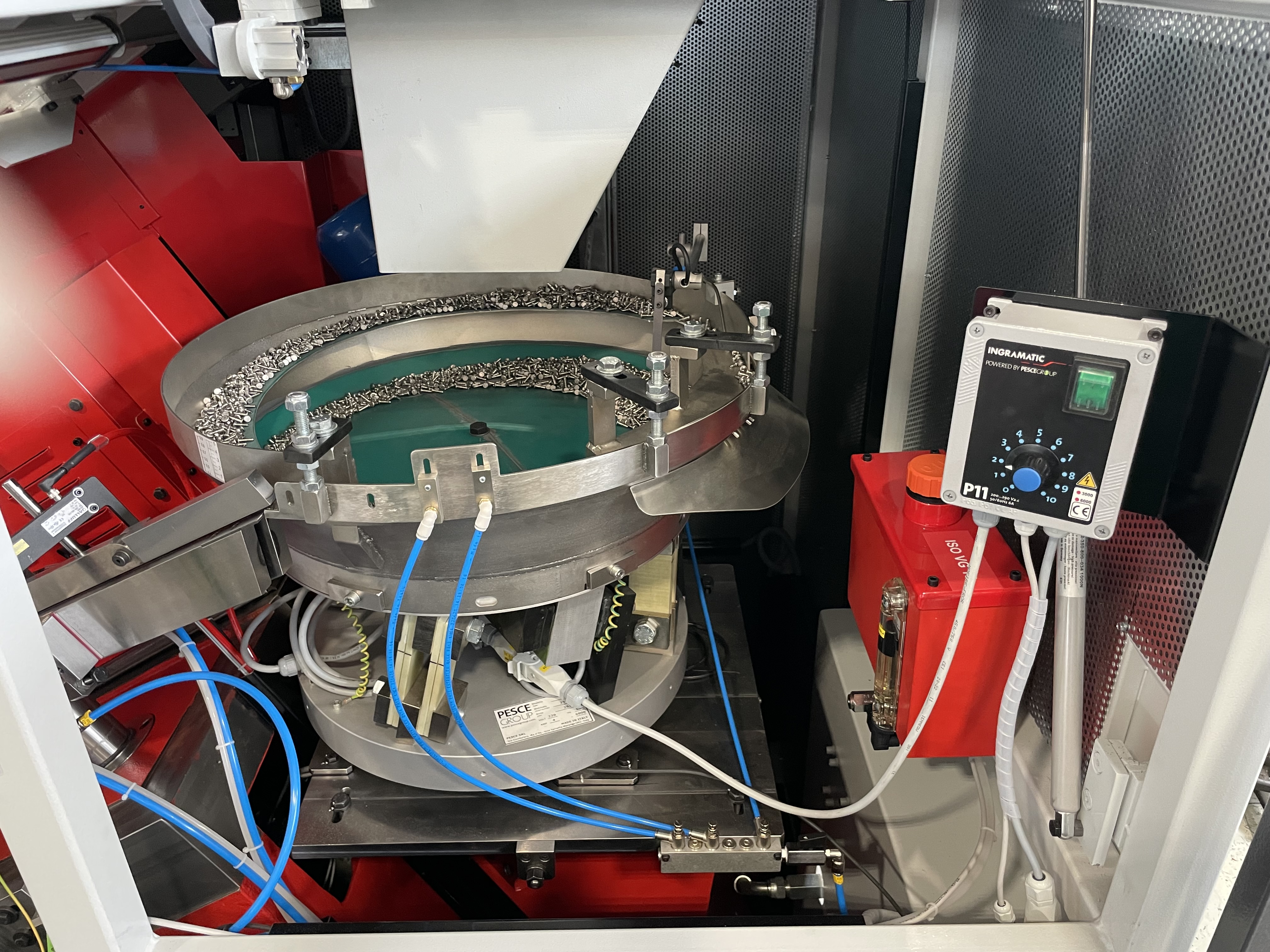

VIBRATORY FEEDER

The blank feeding system is a very important part of the thread rolling machine and therefore must be perfectly integrated with the rest of the machine.

System efficiency depends on the feeding system functionality which must guarantee a constant flow properly positioned parts.

Ingramatic machines have been designed to receive different types of feeding systems.

Small-sized thread rolling machines, up to series 3, normally used for manufacturing screws, are equipped with a vibratory feeder.

Vibratory feeders with digital vision systems are available for special parts that require highly complex selection with maximum flexibility.

A vibratory feeder or a vertical feeding system are available on the mediumlarge thread rolling machines.

During the initial design stage, the Ingramatic technical department performs a preliminary study to define the best feeding solution for the customer.

VERTICAL FEEDER

To assure efficient production, thread rolling machines must be equipped with feeding units specifically designed for the type of part to be threaded.

The vertical feeding system is available for heavy-duty screws, bolts and special parts with various lengths or for the large thread rolling machines with high loading heights.

The Ingramatic vertical feeder consists of:

- A controlled vibration loading hopper that always supplies the correct quantity of workpieces to the vertical lifting device without overloading the container.

- A vertical lifting device with flights with speed control.

- A rotating roller unit with linear vibration for selection and positioning of workpieces before being fed into the feed rails.

This system guarantees perfect alignment with the thread rolling machine rails as it has motorised height adjustment and a joint for angular adjustment.

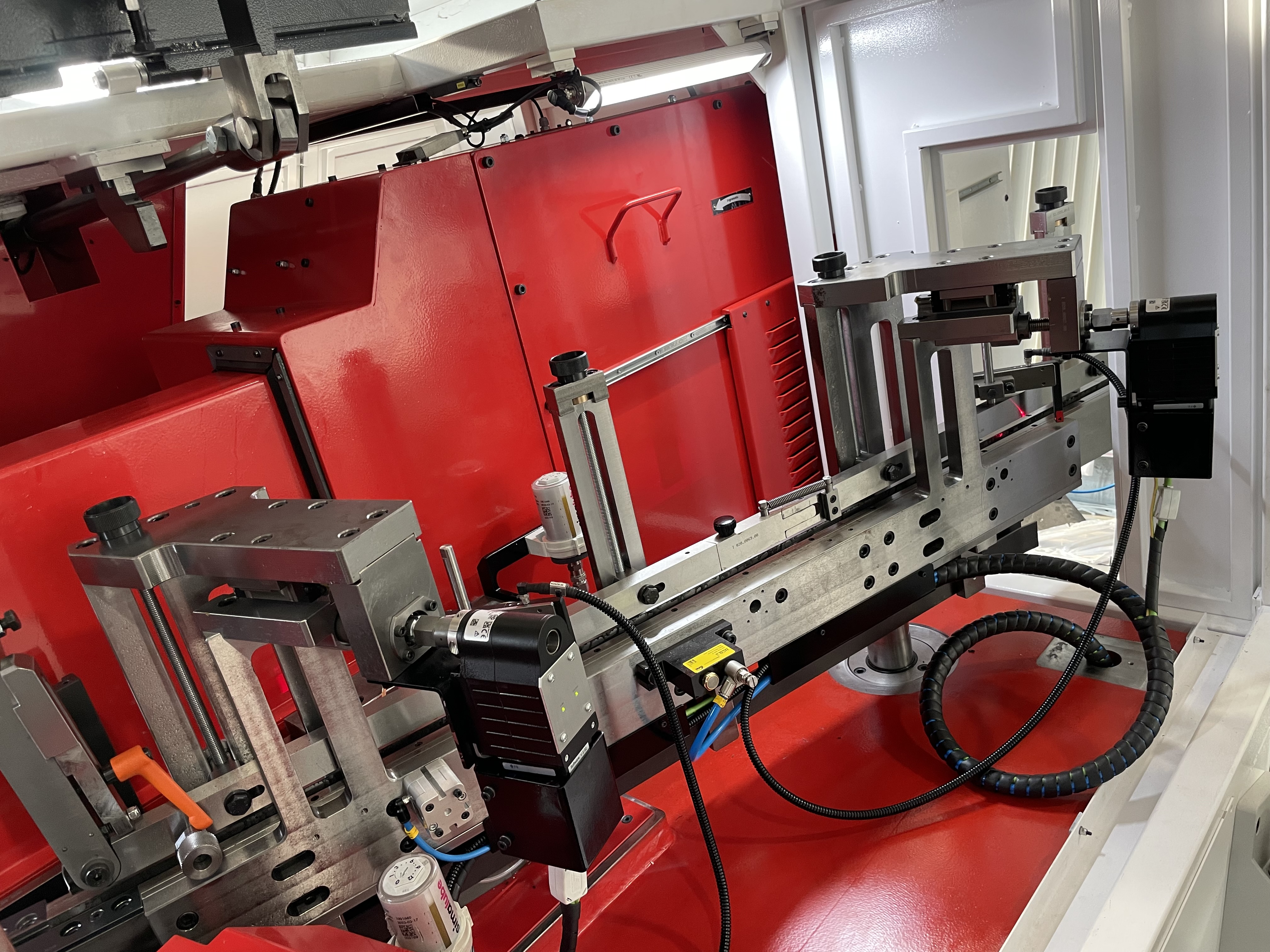

MOTORIZED FEEDING RAILS

The feed guides receive the blanks from the feeder and transfer them, perfectly aligned and correctly positioned, to the starter unit and then to the thread tooling station.

This type of component must be easy to adjust, stable and resistant to wear and tear.

The Ingramatic feeding rails are made with special hardened steel where the parts is in contact to guarantee improved durability. The rails are connected to each other at the top and with their large height adjustment range, they can also load very long workpieces easily. Height adjustment of the feeding rails is motorised with the possibility of memorising the height position for the workpiece that requires machining. Motorisation can also be used to automatically align the rails with the vibratory feeder. As option, the opening/closing of the motorised feeding rails can also be regulated using presetting.

SPECIAL FEEDING RAILS WITH INSERTS

The feeding rails are components that are subject to wear especially when feeding hardened, heat-treated parts or using guide profiles with reduced contact surfaces for special shaped parts feeding.

For this type of application, guides must be made of special steel and they must be designed to simplify maintenance work.

To solve this problem, Ingramatic manufactures special rails with high speed steel inserts (M2) hardened to a high level of hardness increasing the resistance to wear caused by feeding.

This solution is particularly suitable for high-strength bolts, screws and special parts like wheel bolts with conical underheads.

Another advantage of the guide inserts is the ability to replace worn inserts quickly and easily, without having to change the rails.

SINGLE STARTER UNIT

The starter device that inserts the part into the threading dies is very important to achieve excellent machine efficiency and productivity.

An important requirement for users is easy set up and adjustment of this device which must be perfectly synchronized with slide movement.

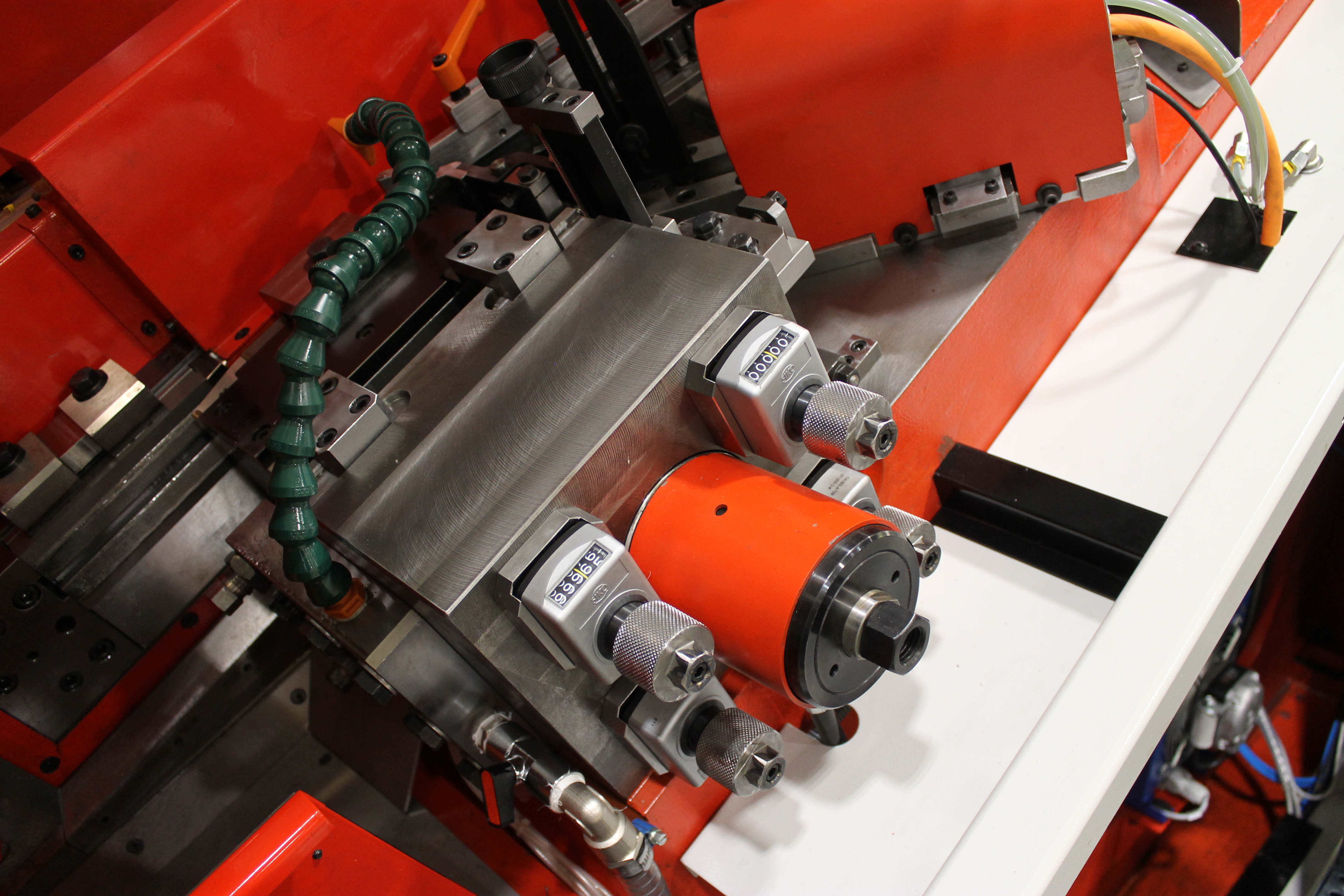

Up to size 4, Ingramatic supplies a single insertion system which is very straightforward and efficient for light, relatively short workpieces. The control of the introduction system is obtained by a torque motor. The motion of the introducing slide is realized by means of a linear movement on a guide with rollers. The machine has a main encoder that controls the encoder of the torque motor, ensuring the synchronism of the two axes. The introducer stroke can be adjusted by the operator panel or by means of the electronic handwheel (optional). The blanks are separated at the feed point by a stop system that positions the workpiece on three points before it is placed between the dies (stop plate, punch and insert). Working in parallel with the insertion punch, the screw stop plate also stops the next blank from passing to prevent double insertion. This unique Ingramatic introduction system allows high flexibility in the production of short and long screws, special parts with special shapes.

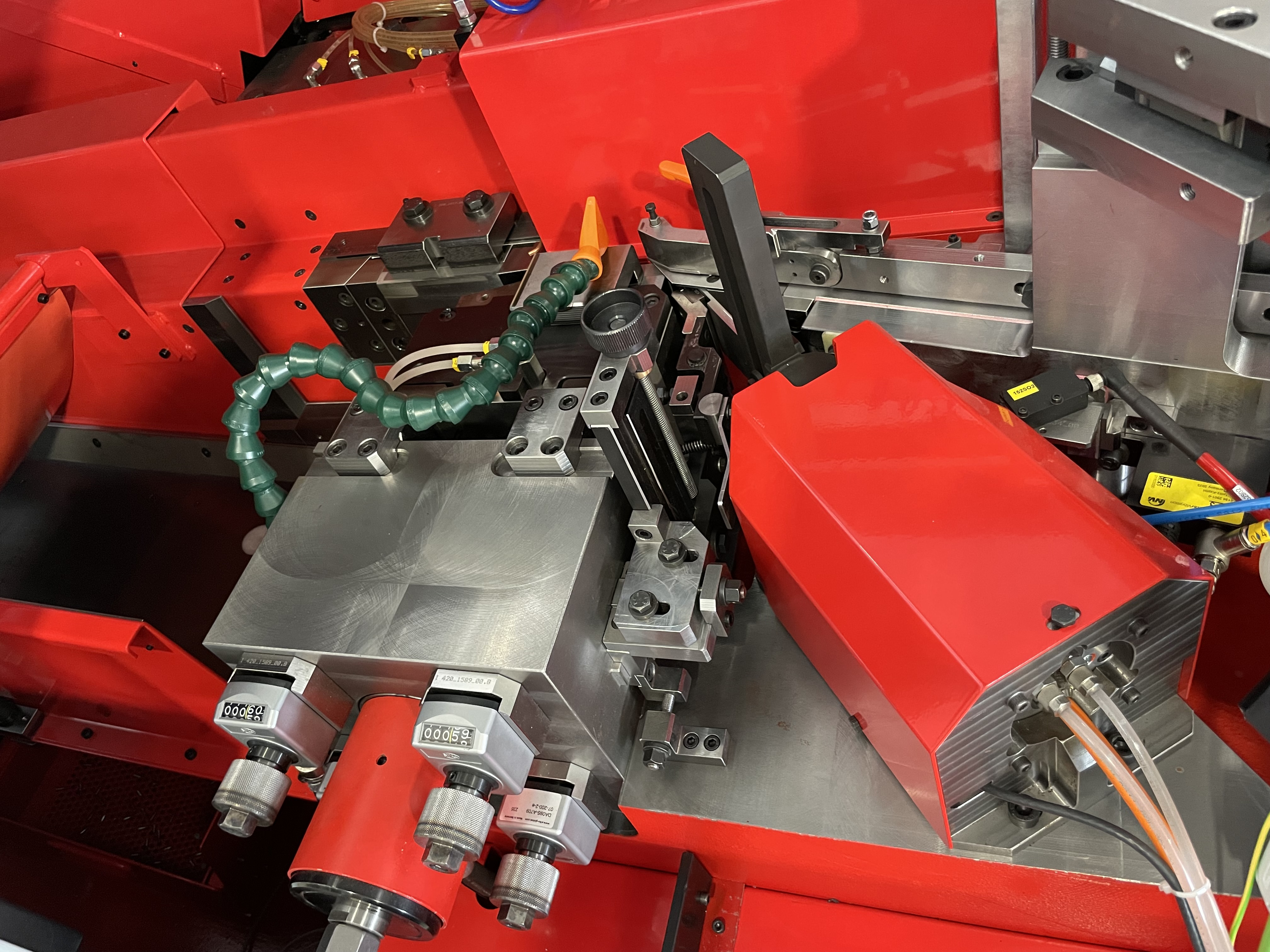

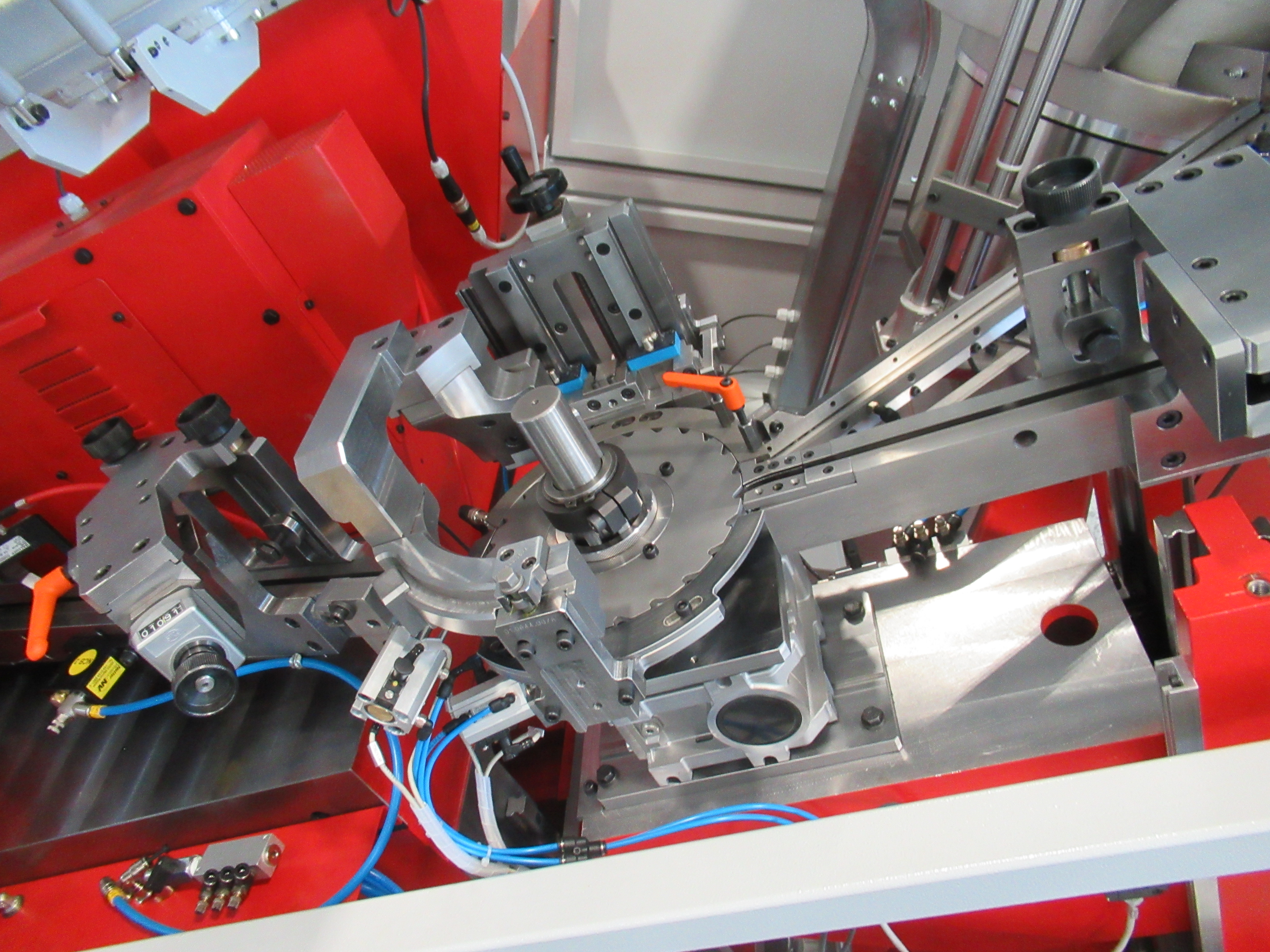

DOUBLE STARTER UNIT

The introduction system for larger parts requires special measures to guarantee constant product quality even at high speed.

The wide product range that undergo thread rolling requires a versatile, efficient introduction system.

The introduction system is activated by two brushless motors in line with two high precision reduction gearboxes. The alternate movement of the slides is obtained through a high precision system pinion-rack. The synchronism of the system with the slide’s position is granted by an encoder activated by the CPU. The blank is pushed between the dies by an introduction system in three phases:

1) Pneumatic separation;

2) Transport and positioning through Brushless motor;

3) Introduction through Brushless motor.

- Separation: the separator pusher guarantees that only one workpiece passes at a time for each insertion;

- Transport and positioning: the first starter pusher moves the workpiece to the die area and places it into the moving die when the slide is in the loading position.

- Insertion: the second starter pusher is timed with the slide to place the workpiece into the rolling dies at an exact right angle to the dies.

The unique Ingramatic double starting system provides a high degree of flexibility in the manufacturing of long and short screws and special parts with special shapes (grooves, wheel bolts, caps, hammer head screws, etc.)

SELF LEARNING ADJUSTMENT OF THE STARTER FINGER STROKE

The adjustment of the introduction system is a fundamental operation to guarantie the perfect machine setting, safeguarding the life of theflat dies and the starter fingers. The timing of the introduction is decisive for the repeatability of the quality of the thread.

Ingramatic has developed a software function to guide the operator through the various setting stages.

The blanks is positionned at the entrance of the dies and from the touch screen panel, the self-learning procedure is activated to define the end point of the stroke of the introducer punch or punches,in the case of double introduction. Adjustment is also possible using the electronic handwheel.

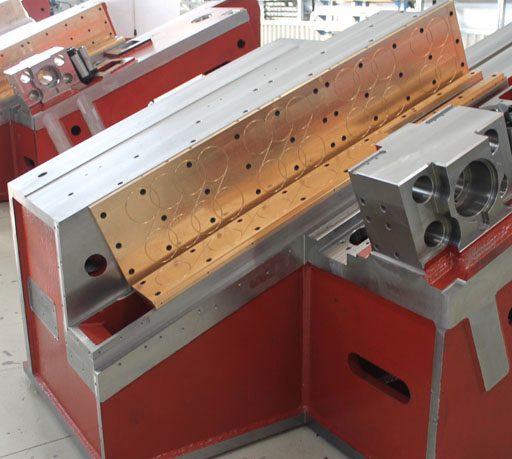

FIXED DIE HOLDER BLOCK

The stability of the fixed die holder block is crucial to guarantee the dimensional tolerances of the parts during production.

This important feature must also be able to perform necessary adjustments with high repeatability and precision when setting up the tools.

On its medium-large machines, Ingramatic has adopted double hydraulic clamping, both vertical and horizontal, of the die holder block. This applies the correct clamping force and is extremely user-friendly and practical to use. The following adjustments can be made on the die holder block:

- Height adjustment by way of a gib on the lower support surface;

- Distance and angular adjustment of the rear support surface by way of four graduated adjusting screws on the operator side. The base in the die holder block fastening area is strengthened with reinforcing ribs that guarantee the necessary stiffness.

From size 3, a set of spacers to be installed according to the diameter to be obtained between the adjusting bolts and the tool holder is supplied as standard equipment of the machine. This application allows a drastic reduction of adjustment time in a safe manner.

SLIDE WITH HYDROSTATIC GUIDES

In the automotive sector and industry in general, there is increasing demand for screws and fasteners that are threaded after hardening and tempering to improve threading precision and fatigue resistance of the components.

The high rolling stresses these parts create require specially designed threaders and options.

From size 5 upwards, INGRAMATIC uses a hydrostatic guide system on its slide that features a high load-carrying capacity with significant damping.

The pressurized lubricant is sent by a distributor to the special bronze guides fixed to the main frame. Due to the hydrostatic pockets in the guides, a layer of oil is formed that evenly distributes the work load and absorbs any impact created when the part is placed between the dies.

The slide, made of high-strength light alloy, with hardened steel plates in the feed areas and moving die housing, reduces the weight of the alternating masses and delivers high production speed.

A closed circuit recirculates the guide lubricant after it has been cooled and filtered. This assures that coolant is not contaminated, extending the coolant life and providing lower operational costs.

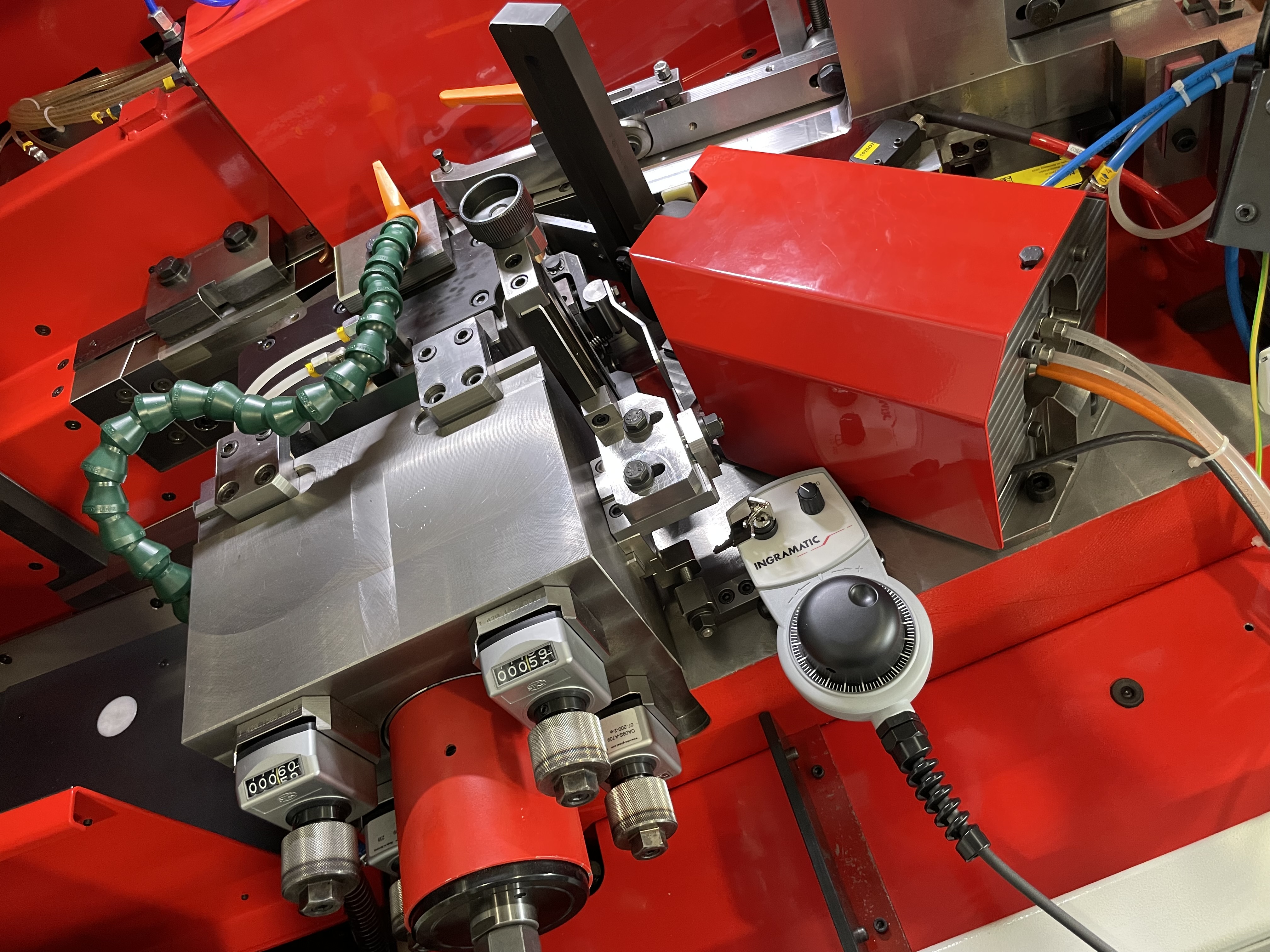

ELECTRONIC HANDWHEEL

When setting up a thread rolling machine it is very important to be able to check the introduction unit operation and correct thread rolling.

Operators need an instrument easy to use, that allows them to work in conditions of maximum safety and avoid any possibility of damaging tools or the machine.

Ingramatic equips its thread rolling machines with an electronic flywheel that can easily be used to perform a number of operations:

- the slide can be moved manually at very low speed without stressing the brake-clutch unit unnecessarily;

- checking die match can be carried out very easily by making the workpiece complete a half-turn and then go back again;

- visual inspection of starter unit at a controlled speed allows the movement to be analysed and rotation to be reversed until the desired position is reached;

- thread rolling product at a reduced speed allows the complete operating cycle to be viewed before starting continuous production.

- in addition, the electronic handwheel allows the adjustment in height of the vib bowl. equips its thread rolling machines with an electronic flywheel that can easily be used to perform a number of operations:

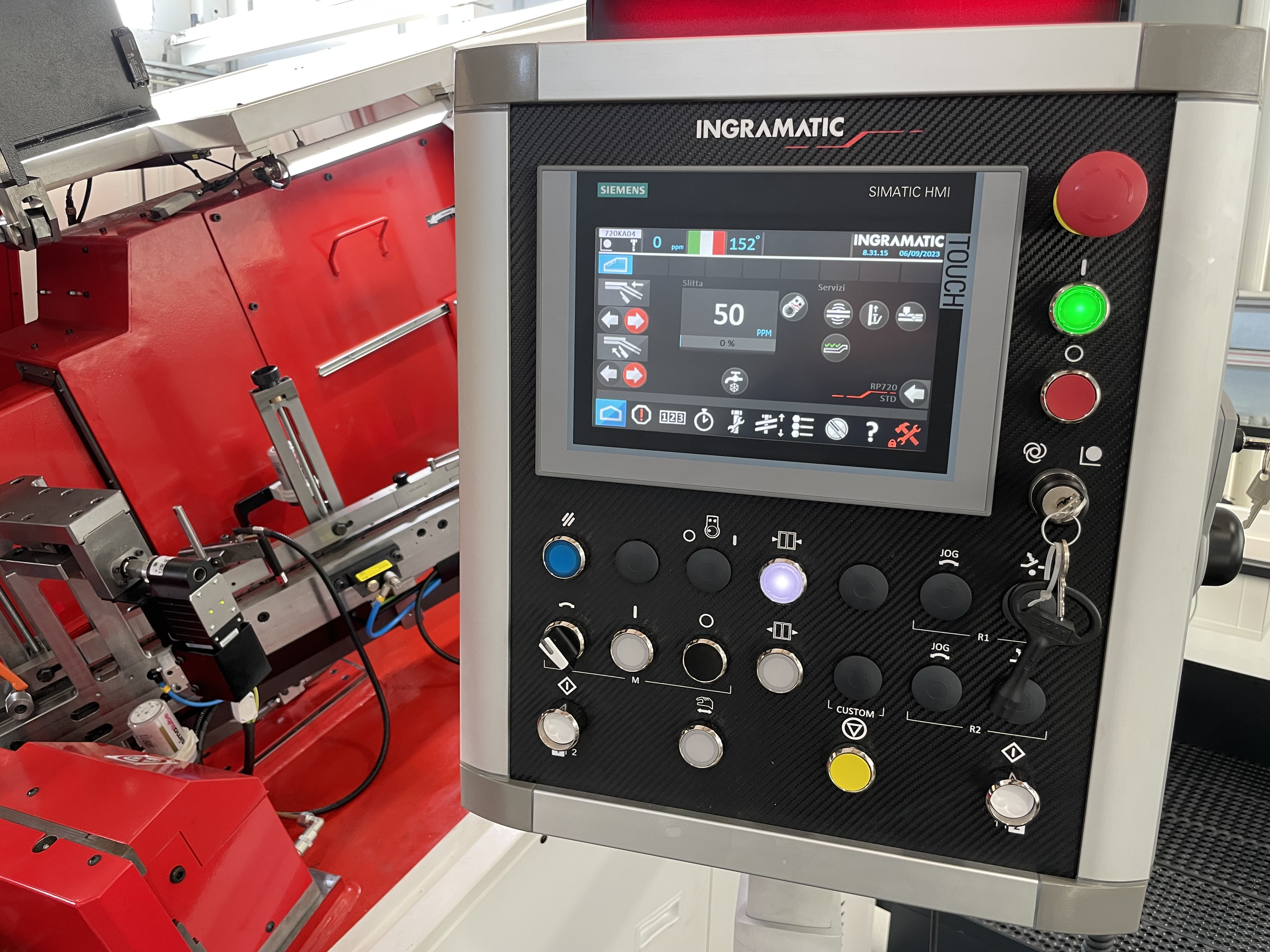

SC-MATIC / MOTORIZATION

With consideration to industrial production with reduced batches, the number of production changeover increases signficantly: this leads to the fact that operators have to handle an increasingly large amount of data during machine setting which must be completed extremely quickly.

The Touch Screen control panel installed on Ingramatic machines allows you to control the machine and its accessories simply and intuitively. The system provides information on production, preventive and routine maintenance and continuous diagnosis of the thread rolling machine operation.

- The SC-MATIC system can memorise a large number of product codes. The supervisor has an Ethernet port for data transfer and a modem for activating on-line customer support.

- The SC-MATIC software has been developed by SACMA on a Siemens platform with the Windows-CE operating system to make use of the thread rolling machines simpler and user-friendly.

LOADING CONTROL

For high quality production, the contribution that control systems make on modern thread rolling machines is of fundamental importance. As well as protecting the tools and moving parts of the thread rolling machine, rolling load and die match monitoring are also an effective implied way of checking dimensional compliance of the parts produced.

The loading control device has been developed in collaboration with Sacma to control thread rolling load and is also available on all Ingramatic machines.

The system has a number of points where loading sensors can be applied with results shown on the display which is integrated into the machine control panel. The control system is either calibrated in Ingramatic to control the loading forces and die match during the thread rolling operation. Each machine can also be equipped for the installation of other loading control systems according to customer requirements.

The detected loading forces signal can also be used to activate the non-conforming workpiece rejection device.

DISCHARGE UNIT WITH PARTS REJECTION

The industry's need for increasingly precise defect-free product is met by developing machines for final control of the product offering production systems that are capable of producing both high quality and eliminating defective product. Correct movement is also vital for reducing the damage inflicted to the workpiece by hitting the machine parts or each other as far as possible.

Ingramatic has developed and fine-tuned a part rejection system integrated with the finished part evacuation chute. The anomaly detected by the loading control system actuates the rejection gate, allowing parts with defective threads to be rejected. Compliant parts are routed to the exit chute with shock-absorbing material so that any damage of threaded parts before entry into the customer's chosen handling device is considerably reduced.

MOTORIZED DIE MATCH

One of the most important set up operations to ensure the thread quality of the part is the die match adjustment. This operation must be performed by experts who can interpret the thread quality after the half-rotation of the blank.

On thread rolling machines, the die match is adjusted by an eccentric mechanical system or a motorized system, changing the starting position of the slide to make the thread profile match between the moving and fixed dies.

Ingramatic supplies as option, the M-Group for the motorization of the dies match.

The die match can be done like all the other adjustments of the machine by the touch screen panel moving the head of the machine obtained through a gear motor coupled with a high precision ball screw and a servomotor. With the electronic hand wheel, the gear motor, and the absolute linear transducer it is possible to position the head and the slide, in order to adjust the dies without using wrenches.

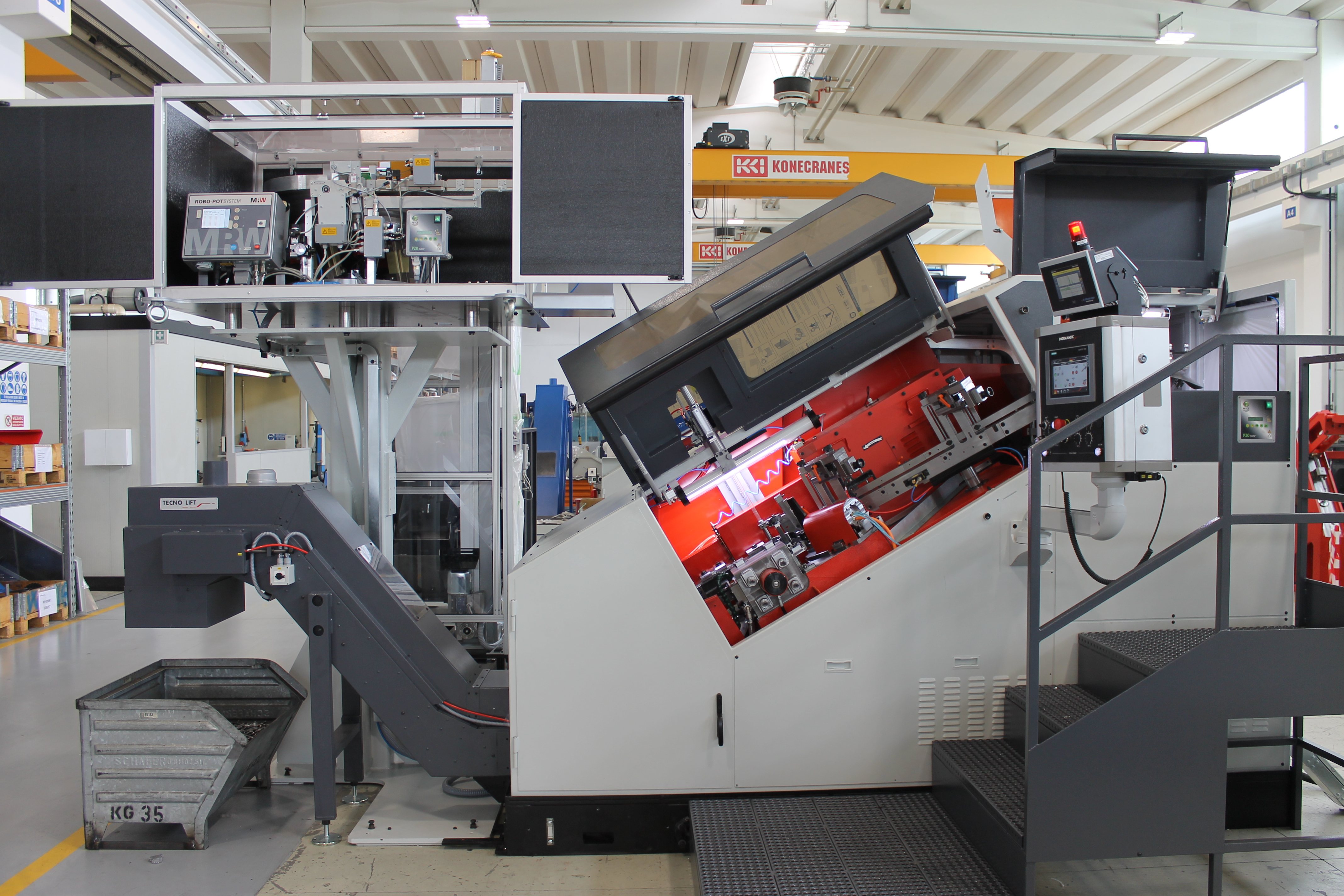

ERGONOMICS AND SAFETY

Modern machine tools must be designed to guarantee the best working conditions for operators with focus on their safety and protection of the environment.

On thread rolling machines, the cabin provides soundproofing (noise level below 80dB) and protection for the operator from the moving parts.

Ingramatic thread rolling machine cabins are designed with solutions that help:

- Operators, by way of wide stairs and platforms, a well designed control panel mounted on a rotating support, convenient access hatches and efficient lighting within the work area.

- Maintenance technicians, with panels that are easily removed for accessing the mechanical parts and service systems.

The platform, that the machine base is fixed to, also contains the technical fluids preventing accidental spillage and seepage into the work environment.

WASHER ASSEMBLY

The increasing demand from the industry for screws with preassembled washers has led machine manufacturers to offer special automatic assembly devices.These devices insert one / two washers or ferrules onto the blank before threading so that they become integral with the screw after the threading operation.

Ingramatic equips its machines with assembly units for one or two washers which are compact in size and extremely flexible.

Without compromising thread rolling machine reliability and productivity, these devices can be used to assembly different types of washers (flat, chamfered, conical, waved, toothed, split, etc.) with a wide range of blank diameters and lengths.

The SC-MATIC software allows the PLC to control washer assembly unit operating easily and intuitively. The sensor control system ensures that all the screws sent to the thread rolling machine have washers and ensures those without washers continue in circulation. For ferrules assembly, a special unit is used where a system of slides with vertical motion introduces the ferrules on the blans.

WASHER AND BLANK PORTER UNIT

The value of an automatic production system is measured by its operating autonomy, i.e. the operating time without operator intervention.

High production efficiency can be achieved in this way which is a pre-requisite for system profitability.

Ingramatic thread rolling machines can be equipped with the Porter, a transport unit for automatic loading of washers and blanks into the respective feed vibrators.

The Porter consists of a vibrating hopper and a lifting system with a fixed column and moving pot. The hopper loads the parts into the pot which lifts on request and trasfer the parts into the vibratory bowl feeder.

A belt loading conveyor is also available as an alternative to the Porter, according to customer requirements.The loading unit is controlled by the machine PLC which permits to load according to the level of parts in the vibratory bowl feeder and signals to the operator when the hopper needs to be reloaded.

TYPE P THREAD ROLLING MACHINES

The thread rolling of stud bolts and headless parts on flat die threading machines is extremely advantageous as far as quality and productivity are concerned.

To obtain this result, a reliable feed system that has been tried and tested is necessary.

Ingramatic can supply P versions of the entire machine range from size 1 to size 7. The parts for thread rolling are placed in-line with the pusher via a tube.

A pneumatic separating device ensures the correct feeding of parts in the work area.

There are two possible solutions for feeding correctly positioned parts.

The thread rolling machine is directly connected to the progressive header by the connection tube. The formed part is sent from the last station directly to the thread rolling machine.

The second solution involves a feeding system with a vibrator bowl feeder or elevator depending on the part length, and an orientation system which is either mechanical or uses a digital camera.

POINTING UNIT

Many screws or bolts require a chamfer or a point shape before thread rolling.

There are many different types of points that can be made easily and at low cost by cutting rather than using complex, higher cost forming tooling.

The Ingramatic pointing unit spindle is mounted on a motorized slide so that it can easily be set to the correct position for the different lengths of blanks.

This position can be memorized to speed up set up times.

The blank is first placed between two fingers which clamp the part and lower it to the pointing tools, where the point is cut.

The scraps are ejected with the coolant and collected in a special container where the liquid is filtered and recirculated.According to customer preferences, the pointing unit can be a single machine or a work unit combined with the thread rolling machine to point the workpieces before thread rolling.

COMBINED THREAD ROLLING MACHINE

Since flexible production has become vitally important for penetrating new markets, machines must be customised according to customer requirements and strategies.The challenge in recent years is to apply the concept of "Lean" production by creating efficient production units with the shortest possible production cycle, reducing the number of secondary operations on parts to be produced.

Starting with its standard, Ingramatic offers solutions to meet the most complex requirements with its Modular system. For example, the application of different forming systems on the same machine makes possible to produce multi shape parts with only one loading operation, reducing intermediate stocks and possible washing operations. To meet this challenge, solutions are proposed that allow blank loading in a continuous and automatic manner, by passing the part first through the rotary rolling station and then through the flat die rolling unit. In this way, rolling operations with different diameters, threads and grooves can be combined, efficiently using a single production unit.

TOOL DESIGN

The changing world of thread rolling encourages designers and technicians to develop increasingly complex products using the cutting-edge technology available.

When planning new investments, it is very important to be able to count on a reliable partner who is skilled in designing and developing equipment that can satisfy special requests.

Ingramatic's consolidated experience in thread rolling and search for technological solutions in close collaboration with customers make it an ideal partner at this critical stage who will help to accelerate project development times.

A team of engineers, using highly innovative simulation and design software, works together with customers to identify the best product manufacturing solutions.

By collaborating with leading companies in the field, Ingramatic can also offer efficient “turnkey” production systems.