NEW ULTIMATE - WARM FORMING PRODUCT LINES

02/02/2021 The hot forging (HF) was the first and for many years the only process applied to form shaped metal pieces. In the second half of last century, pushed by the needs of mass production, the cold forming (CF) becomes widespread, initially to produce bolts and screws and after also special parts, solid and hollow. The warm forming (WF) process stays in the middle of cold and hot processes, more near to cold for precision, accuracy, tools and machinery.

The main difference among processes are the temperature of the material to be formed. At cold, all the materials start the deformation from room temperature. At hot, the steel blanks are heated in the range from 950 up to 1250°C. At warm, the operating temperature is lower and don’t exceed 900°C for steels.

The total energy spent to perform WF process is less than HF and quite similar to CF, because the heating energy is compensated by the lower amount of deformation energy.

The tools are generally more durable for cold forming, less for hot forging and in the middle for warm forming.

By WF it is possible to produce more difficult parts than CF and also the range of suitable materials is much wider. Despite the interesting features of WF process, the development is still quite limited for different reasons: dedicated machinery, specific lubricants, effective coatings.

A common question when approaching the WF process is about the heating temperature to be used. The goal is to define for each material the right temperature, enlarging the plastic field and the limits of deformation just enough to allow the required deformation.

• For low carbon steels the WF process is not so interesting, because typical materials for cold forming.

• High carbon and alloy steels require temperature in the range of 600-700°C.

• Austenitic stainless steels are heated to 200-300°C to form solid parts and up to 500°C to produce hollow parts by backward extrusion.

• The typical materials used in aerospace industry, like titanium alloys and Nickel superalloys, need temperatures from 500 to 850°C depending on quality of material and shape of the part.

In the early eighties Sacma developed and built WF progressive headers to produce 100Cr6 ball bearing rings.

In 2008 the first fully integrated warm former designed for aerospace fasteners was presented to the market

The key point for WF machinery is to handle the temperature without affecting reliability and precision.

For high temperatures the technology becomes more complex and exclusive. When the products don’t require important pre-heating, the machine could be more simple and less expensive.

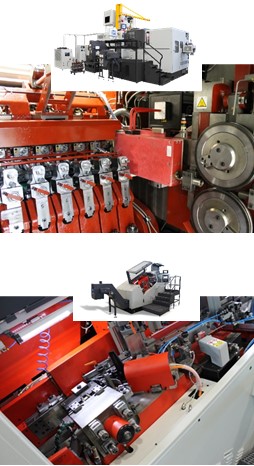

Focusing the target of “right equipment for each demand”, Sacma is now presenting the ultimate WF headers product line.

The offer is well articulated for a range of wire diameters from 4 to 25mm and of temperatures from room to 900°C. The 5 and 6 die headers WF are size 2 (wire max 10,5mm) , size 3 ( 15mm ), size 4 (20mm) and size 5 (25mm):

- For size 4 and 5, there is only one WF version covering all the field up to 900°C.

- For size 2 and 3, there are different models defined by the max reachable temperature: WF300, WF500 and WF900.

In the Sacma product line it is possible to find the machine which specs are perfectly matching the parts and the materials to be produced.

To complete the Sacma warm former line, Ingramatic introduces their new Warm Forming rollers. Combining the heavy duty design and the features of the revolutionary I-Thread, the WF rollers provide a significant increase in thread quality, productivity and efficiency by rolling all shapes of bolts, screws, studs and parts made of materials difficult to be rolled by cold machine features include:

• new feeding rails allowing the installation of the induction coil with an exclusive design

• the generator from 12 to 30KW,

• the high frequency inverter box

• the optical pyrometer

• the chiller

• and a coolant system to thermoregulate the stationary die holder and the feeding rails

A system of cadencers of selectors manage the parts out the exit of the induction coil to ensure the parts are delivered to the starter unit at the right temperature.

During the production, to manage the quality and the repeatability of the part dimensions, the pyrometer and the load monitor check each part and reject the n.c. parts automatically without stopping the machine and the heating unit.

Ingramatic said that for a complete changeover, 30 minutes are necessary and for a changeover consisting only on the part length, 10 minutes are enough. This makes the rollers very competitive for the Aerospace market where the production quantity are very low.

This is possible because the Warm Forming rollers is part of the I-Thread machine design, the revolutionary line of thread rolling machines emphasized by the following points:

• Quick Setup, all adjustments fully motorized.

• Rigid, the one-piece iron casting bed frame including the reaction block designed to counter the stresses caused by thread rolling of special materials and profiles.

• User friendly / Ergonomic, I-Panel Touch Screen controls with all WF functions integrated in a page dedicated to the Warm Forming unit and a constant control thanks to the main page showing the real temperature and the KW necessary to warm the parts.

• Flexibility, Single Starter unit driven by servomotor and for the bigger machines, the servomotor for the die match adjustment with load monitor control and hydraulic clamping of the drive unit.

• Simple to use for the operators, the Electronic handwheel can be used for all machine adjustments - die match – rail position - starter unit; eliminating the use of hand tools.

• High speed & Reliability thanks to the precision of the starter unit, the unique design of the feeding rails and the square design of the frame.

With this new WF line, Sacma Group, already leading the market of headers made for special materials, completes perfectly its whole range of machines and now is able to provide the right equipment for each demand specially for the Aerospace and other markets.

Go Back to the list