TAPPING MACHINES /

COMBINED MACHINES /

TRANSFER MACHINES /

TURNING MACHINESAfter the acquisition of the Tecno Lift Srl company in 2018 making loading and moving systems for fasteners, Sacma Group continues its strategy to serve better its customers with more equipment’s for the fastener industry. Sacma Group is announcing to have acquired shares in the capital of HS Automazioni Srl. HS Automazioni supplies a wide range of automatic machines to run pre formed parts obtained by cold forming. It is the logical step which was requested from the Sacma customers looking for a complete turkey solutions from one solid and stable supplier making everything inside. Sacma Group has now a full range of machines to cover all aspects of fastener production.

HS Automazioni Srl was initially specialized for supplying hardware and software system for the general industries and to design CNC multi spindle turning machines and transfer systems. In 2014, HS Automazioni started to manufacture automatic tapping and drilling machineries under the license of the ASPE company which has been making machinery since 1976 and; well known as one of the best supplier for tapping and drilling machineries with more than 1.000 machines started up around the world. Today based on ASPE know-how and on the HS Automazioni engineering expertise, the company with about 25 employees designs and manufactures a range of machines rebranded HS ASPE. Which is consist of tapping machines, combined machines, transfer machines and multi spindle turning machines. The company is located in Mathi close to Turin, about 80 miles from Sacma headquarter. All components and electric equipment’s are made and programmed by the HS Automazioni technicians in their factory.

HS ASPE is following the industrial strategy of the Sacma Group with outstanding assembly lines divided by product family and following a modular system concept with serial production to make the machines extremely precise and durable. The company will move to a new plant within September 2020 in the same town with cutting edge equipment’s to ensure its growing activity.

According the experience of Sacma Group with the S-TOOLING program, secondary operations following the cold forming process means: ADDED VALUE ON THE FINAL PRODUCT and COLD FORMING PROCESS SIMPLIFICATION. Below are the Guide to the system describing the four machine families :

The

Automatic Tapping Machines are based on the reversible spindle architecture, mechanically driven by lead screw or brushless synchronized motion systems. Internal threads, within the range M2 to M36 can be executed with standard taps in both the technologies, cutting and forming. Modularity is at the base of the machines. In relation to the characteristics of the application, it's possible to place single/double spindles having that way two autonomous working areas. Flexibility is also maximized since the possibility to work contemporary two different parts in a completely autonomous process. Precision in operation is achieved by means of the structural rigidity of the frame and the very fine design and engineering of the positioning/clamping devices. Orthogonality and concentricity as well as the other dimensional/geometrical features, are so lifelong guaranteed. In terms of productivity, a configuration with four spindles, with an output rate up to 200 pieces/minute, represents the most complete machine architecture.

Drilling and Tapping Combined Machines

Drilling and Tapping Combined Machines are used to execute complementary operations in addition to the tapping. Operations like drilling, boring, facing, chamfering are so performed, sequentially or in overlapping, exploiting the single positioning/clamping of the part under process. That way the output rate is strongly increased. A top performer machine can be gifted with 2-3-4 working units.

The

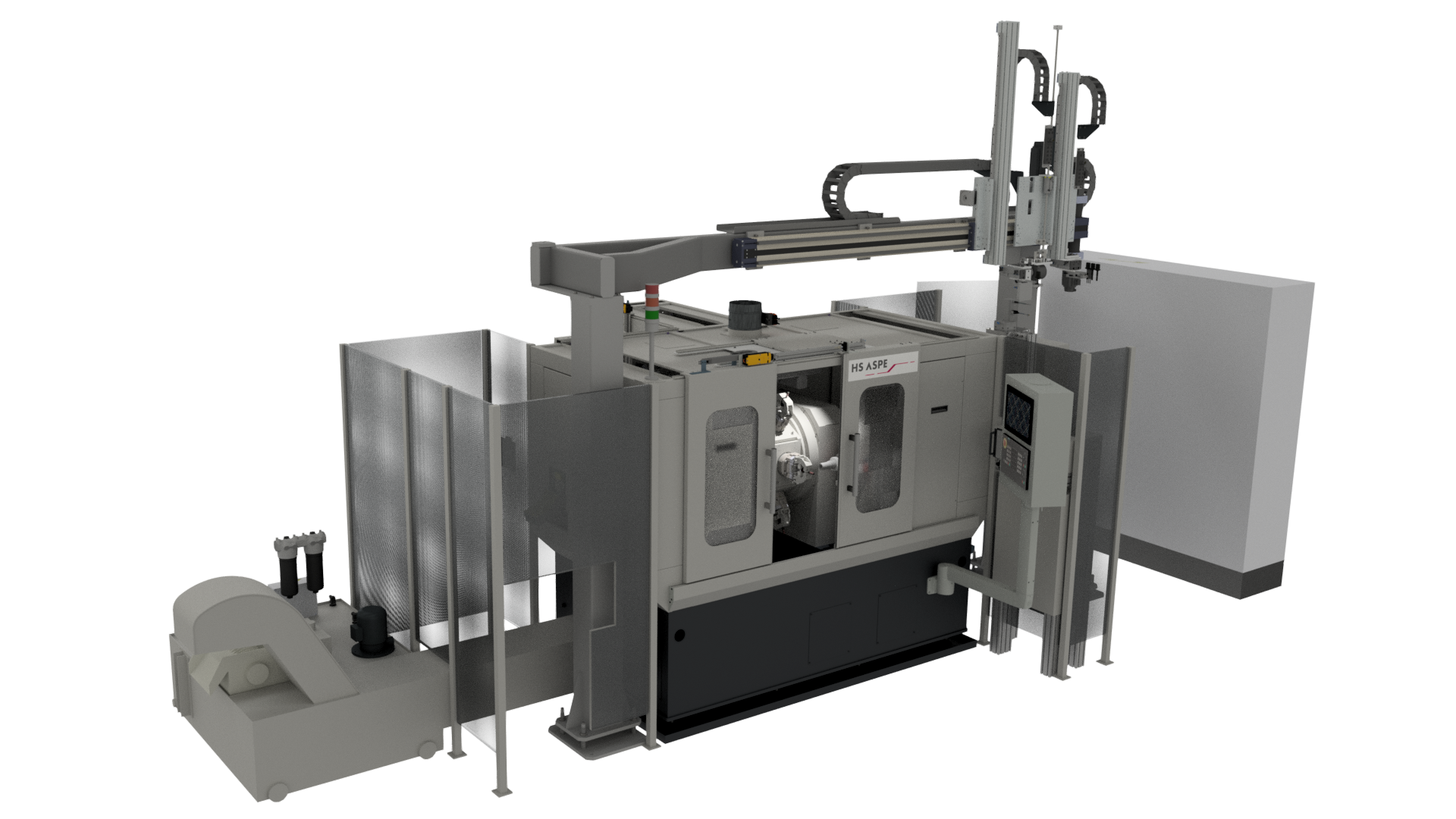

Transfer Machines are conceived to work out medium/big sized batches of parts, characterized by the need of high precision. At the core of the machine there is the permanent clamping system, pneumatically or hydraulically powered, which combines precision, repeatability and rigidity. HS ASPE transfer machines are built on a peculiar bed which guarantees very high rigidity joined with flexibility. This peculiarity allows the adoption of the top ranked equipment (Direct Drive Technology) and then the achievement of the top of operational performances inside the very high customization degree.

The range of

CNC Machines for secondary operations meets the needs of productivity and precision required by this specific market. The range includes three machine architectures: Single spindle, Double spindle and Multi Spindle (four or six) on indexing table. The machines are gifted with leading-edge equipment (Direct Drive technology coupled with Torque motors), allowing top performances coupled with top precision. Multi spindle configuration allows the maximum productivity, making possible the execution of diverse operations in overlapping modality, such as parts loading/unloading, keeping the autonomy over the single spindle. Parts sorting and feeding, that as operations are at the base of the performances, are designed and engineered started from the drawing, optimizing since the beginning the entire in-machine process. Most used solutions foresee bowl vibrators, linear vibrators, motorized belts, like-a-man robots, pick and place units.

The sales and technical centers of Sacma Group are in charge of the distribution of the HS ASPE machines around the world. For more information about the product HS ASPE, please visit the website.

more info .